The Foundation

Of Your

Manufacturing

Success

Powering High-Volume Production with Precision Injection Mold Tooling

When it comes to injection mold tooling, you deserve a partner who understands the pressures of high-volume production. At SyBridge, we design, build, and validate production tooling that serves as a seamless extension of your operation. Achieve unparalleled efficiency and quality with your best-in-class injection mold tooling. We are a trusted supply chain partner, dedicated to ensuring your project is executed on time and within budget.

Engineered for Consistent Performance

For demanding applications where consistency, quality, and cost control are non-negotiable, consider SyBridge as your strategic partner. We go beyond simply building molds—we engineer comprehensive solutions that seamlessly integrate into your manufacturing operations, supporting your demand with precision and expertise. Our precision engineering ensures consistent part quality and extended mold life, maximizing your investment.

More About Our Design & Engineering Process

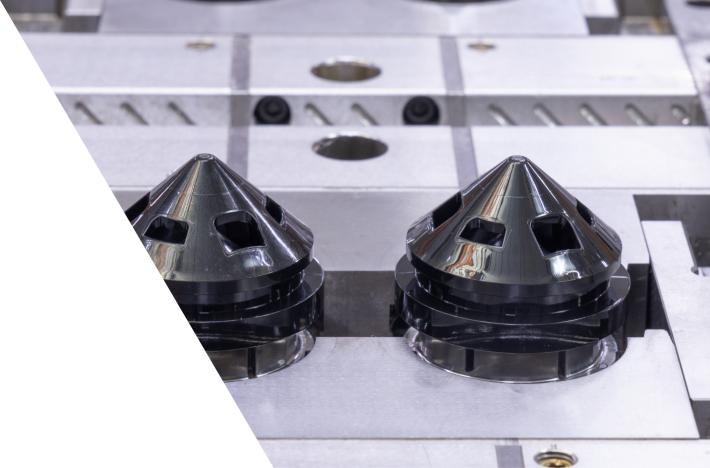

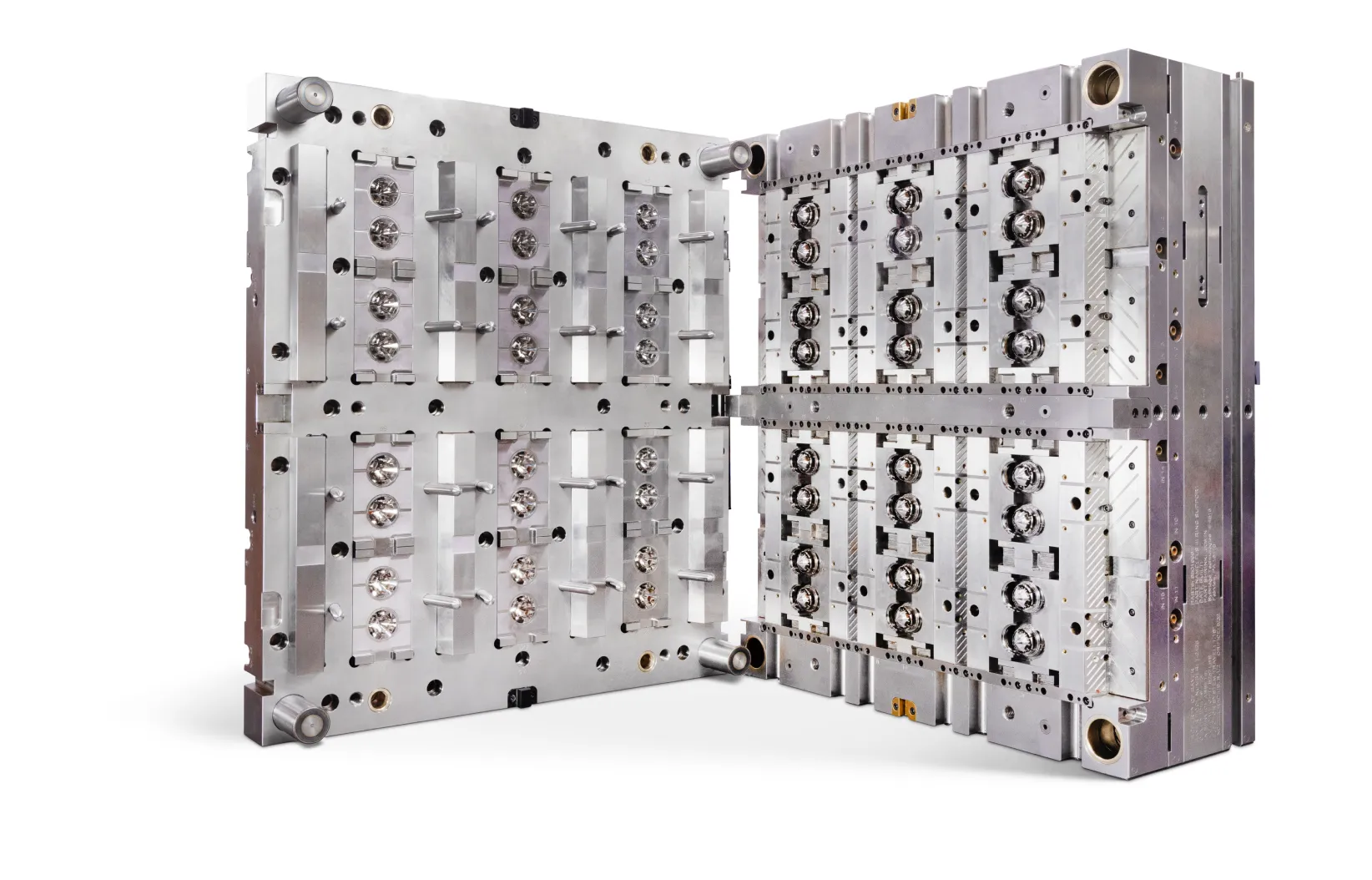

Full Service Capabilities for Complex Requirements

Whether you’re working with intricate micro-molding or large, complex, high-cavitation molds, we have the expertise and technology to handle it. We specialize in precision engineering with tight tolerances (0.0002”) and a wide range of tooling technologies to support your unique production requirements. From multi-shot to stack molds, our custom solutions are meticulously tailored to your specifications.

Talk to an expert

Specialized Technologies for Precision Results

Custom Engineered Solutions for Demanding Markets

We understand the critical requirements of your industry and offer custom tooling solutions designed to meet demanding standards in:

Healthcare

We understand the critical requirements of your industry and offer custom tooling solutions designed to meet demanding standards in:

Packaging

We understand the critical requirements of your industry and offer custom tooling solutions designed to meet demanding standards in:

Consumer Goods

We understand the critical requirements of your industry and offer custom tooling solutions designed to meet demanding standards in:

Mobility

We understand the critical requirements of your industry and offer custom tooling solutions designed to meet demanding standards in:

Industrial

We understand the critical requirements of your industry and offer custom tooling solutions designed to meet demanding standards in:

Dedicated Program Management from Design to Production

We provide a seamless and efficient experience through dedicated program management. You’ll have a single point of contact for clear communication, ensuring on-time delivery and strict adherence to your quality standards. Our expert team offers comprehensive support, from design assistance and DFM (Design for Manufacturability) analysis to a smooth transition through all stages of the product lifecycle.

Single-Source Global Resource

With 17 locations across 5 countries, including 15 manufacturing facilities, we combine local expertise with global scale to support your tooling programs worldwide. Our network allows us to select the optimal build location for each project, balancing quality, cost, delivery, and tariff exposure—no matter where your operations are based.

Explore Our Locations

Your Tooling Manufacturing Options

Every tooling program is different from a quality, cost and delivery standpoint. That’s why we

offer three distinct build options, each designed to address specific priorities. Our team will

guide you to the approach that delivers the right balance of cost, quality, and speed that meets

your requirements.

1. Domestic Build

SyBridge provides the complete solution—DFM, design, build, and validation. With in-house full-service capabilities, we help you achieve world-class quality, cost, and delivery.

2. Hybrid Build

We deliver DFM, design, build, and validation in-house, while sourcing select components through our Global Supply Network (GSN). This approach builds the best cost without compromising quality or performance.

3. Supply Chain Fufillment

For customers with existing suppliers or specific sourcing needs, SyBridge can manage your global tooling suppliers, providing landing services to test and validate third-party tools and parts at your dedicated SyBridge location.

FAQs

SyBridge specializes in a wide range of production tooling, including high cavitation molds, multi-shot molds, micro-molding, stack molds, insert molds, and in-mold closing, and in-mold decorating—with actions that include sliding or telescoping shutoffs, unscrewing, lifting, and collapsing cores. Each is tailored to meet your volume, complexity, and performance requirements.

We offer three sourcing strategies:

Domestic Build: SyBridge provides the complete solution—DFM, design, build, and validation. With in-house full-service capabilities, we help you achieve world-class quality, cost, and delivery.

Hybrid Build: We deliver DFM, design, build, and validation in-house, while sourcing select components through our Global Supply Network (GSN). This approach reduces cost without compromising quality or performance.

Supply Chain Fulfillment: For customers with existing suppliers or specific sourcing needs, SyBridge can manage your tooling suppliers, providing landing services to test and validate third-party tools and parts at your dedicated SyBridge location.

We design production tooling with scalability in mind. Our team ensures smooth transitions from pre-production or prototype molds to high-volume production, optimizing gating, cooling, ejection, and process validation to reduce risk and maximize performance.