Prototype Injection Molds to Get You Ready for Production

Accelerate Your Speed to Market with Expert-Built Pre-production Tooling

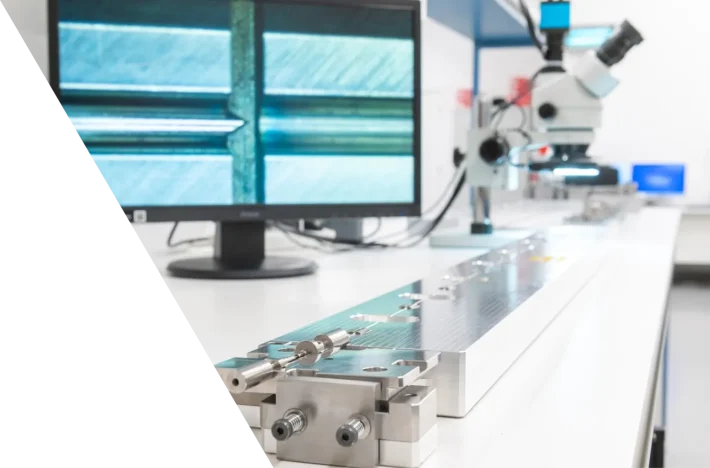

Prototyping is a critical step in turning your vision into reality. At SyBridge, we’re experts in designing and building pre-production molds that help you quickly and affordably validate your design, reduce overall program costs, eliminate risk, and accelerate your path to market. As your trusted partner, we help you move forward to production with confidence—bringing innovative products to life with the accuracy, quality, and consistency you demand.

Our Prototype Tooling Options

Choose from three specialized tooling solutions for efficient development:

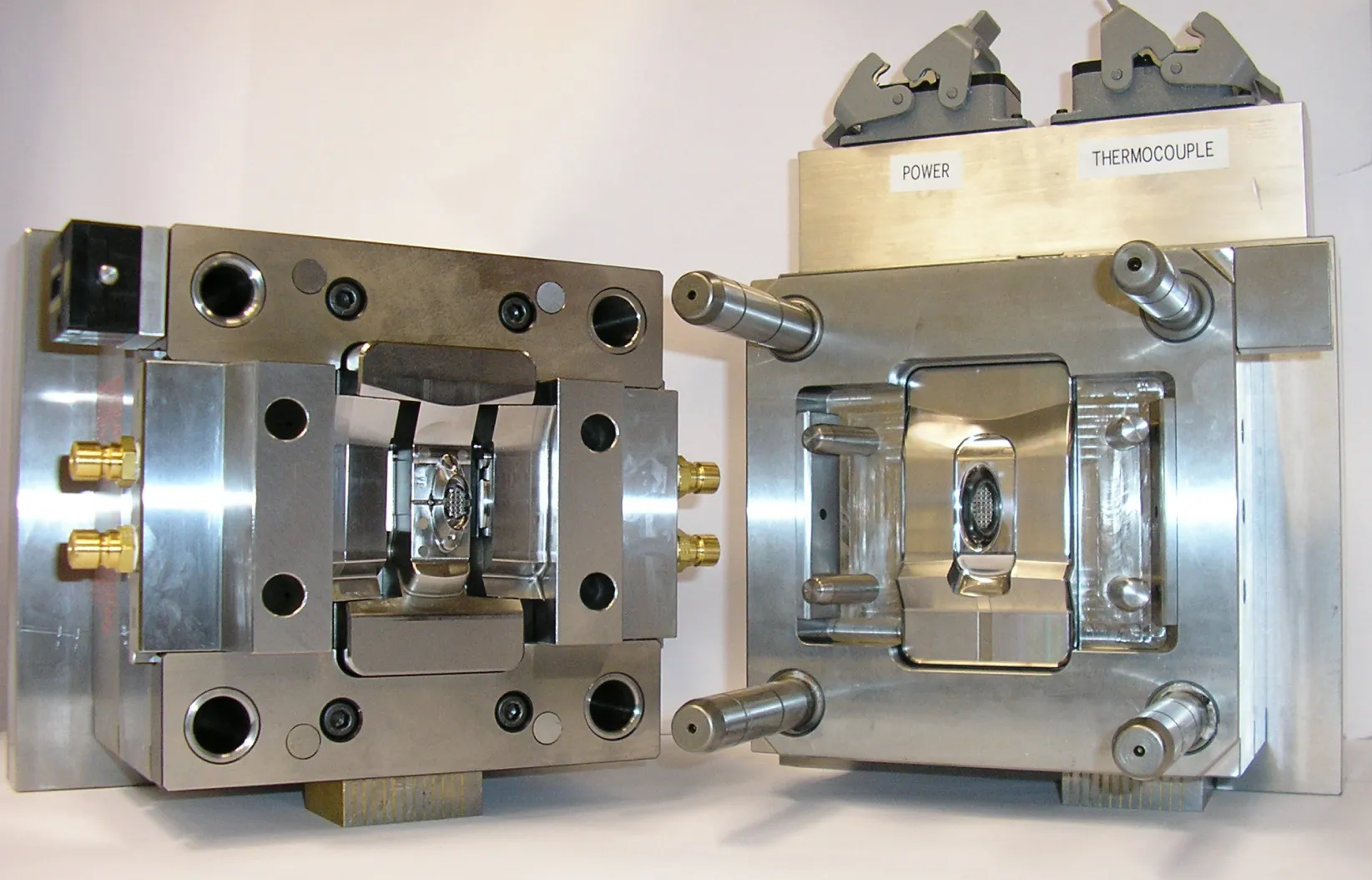

- Cassette Molds: Easily loaded into a universal base, each cassette enables rapid production of small volumes of production-equivalent parts for testing.

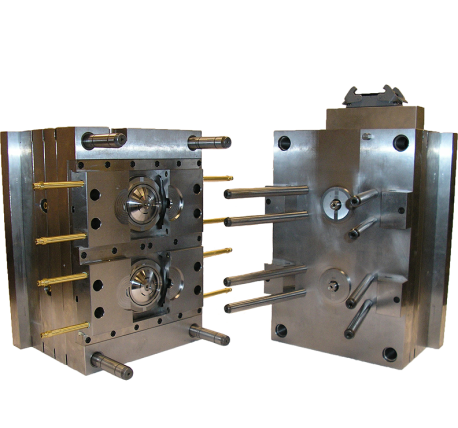

- Modular Interchangeable Tooling: Streamlined inserts reduce material use and machining time, helping you change over quickly and reduce cost.

- Soft Steel & Aluminum Molds: Fast fabrication and high shot counts make these ideal for quick prototyping cycles.

Why Consider Pre-Production Tooling?

Validate Designs Fast and Affordably

- Test form, fit, and function

- Catch design and material issues

- Simulate and validate in weeks at lower cost

Ensure Production

Readiness

- Test materials, validate cooling, gating, and ejection choices

- Optimize cycle times and process parameters

- Avoid inefficiencies and downtime

Accelerate Time

to Market

- Iterate quickly through prototyping

- Prevent rework by catching issues early

- Minimize bottlenecks, reach market testing faster

Scale Up to Production, Seamlessly

We build prototype molds with future scalability in mind. Our production-minded approach informs final mold gating, cooling, and ejection requirements. This ensures a fast and consistent transition from prototype to high-cavitation production tooling, leveraging the same trusted partner for unparalleled continuity.

Fast, Flexible Pre-Production Solutions

FAQs

A pre-production injection mold is an early-stage mold designed to produce limited quantities of parts for testing and validation. It allows you to verify fit, form, and function before committing to a production-level mold, reducing risk, cost, and time-to-market.

Lead times typically ranging from 3–8 weeks to receive parts, depending on part complexity and tooling type / selected pre-production process.

Yes. Our prototype and unit molds are designed to produce parts with tight tolerances, intricate geometries, and functional features, enabling early validation of even the most complex designs. Our team works closely with you to recommend the optimal design and molding approach, ensuring you can test and validate what matters most before committing to production tooling.

We commonly use P-20 steel and aluminum for prototype tooling, depending on the part’s intended function, shot volume, and testing requirements.

We combine engineering expertise, advanced simulation, and precision tooling techniques with a customer-focused approach. Our proven experience ensures accuracy, consistency, and reduced time-to-market across diverse industries.