Comprehensive Tool & Part Validation Services

Minimize risk, maximize quality, and achieve consistent repeatability.

Achieving reliable, high-quality production starts with thorough validation. At SyBridge, our certified facilities and expert team offer meticulous tool and part validation services to help minimize risk and ensure your parts work as designed. From mold qualification to final inspection, we provide complete solutions to support consistent performance and smooth production.

In-House Mold Qualification & Part Validation

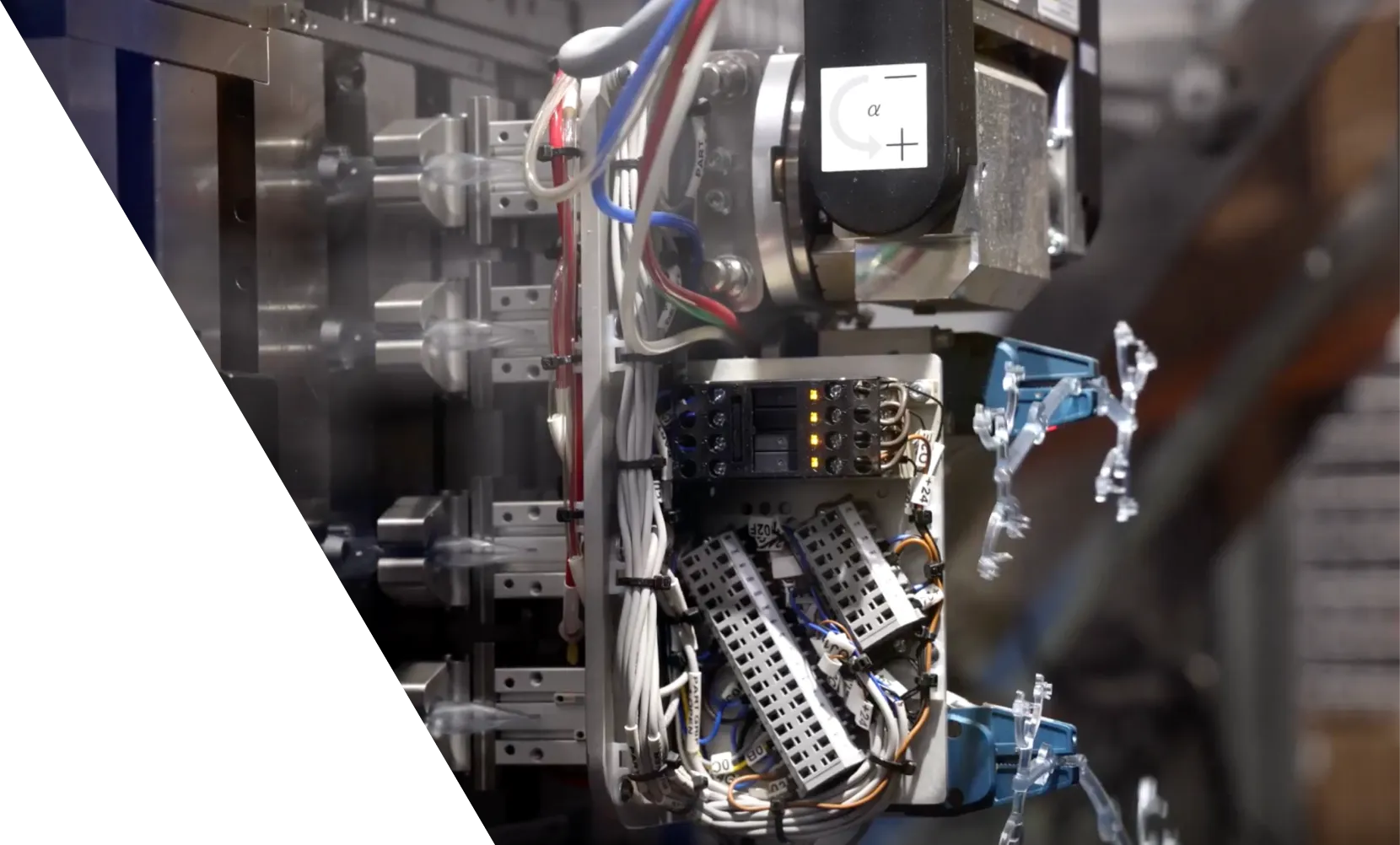

We perform Mold Final Acceptance Tests (MFAT) and part inspection services in-house, replicating your production environment to fully qualify new and restored molds.

- Fully Equipped Facilities: 7–3300 ton presses and Class 8 Clean Rooms

- Complete Mold Qualification: Functional Mold Testing (FOT), Process Development (SIM), IQ/OQ/PQ, Scientific Molding, First Article Inspection, DOE, and comprehensive documentation

- Quality Assurance: Internal/external protocols, certified facilities, in-process verifications, and final inspection

- Seamless Project Management: Single point of contact keeps operations running smoothly

Certified for Excellence

Our certified facilities around the world meet leading industry standards, from ISO 9001 and IATF 16949 to AS9100D and ISO 13485, supporting major brands in highly regulated markets.

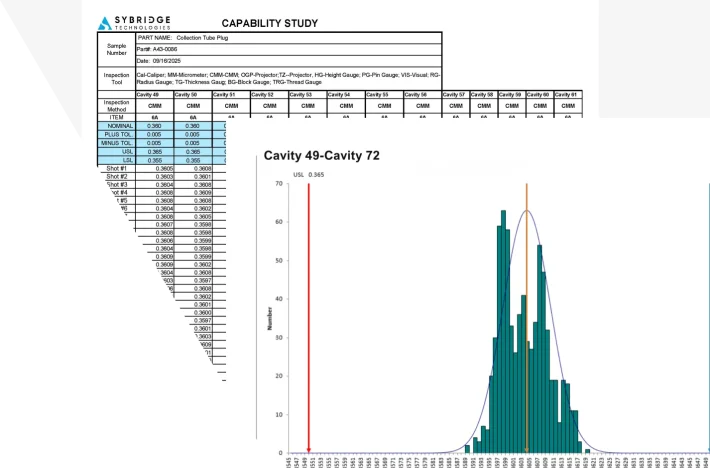

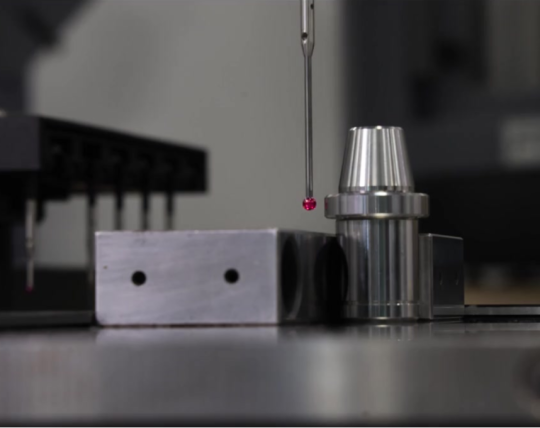

Cutting-Edge Inspection Technologies

Our ISO-certified facilities use advanced inspection

technologies operated by experienced quality professionals,

validating your tool and parts to ensure your critical dimensional requirements are met.

- Coordinate Measuring Machines (CMM) for precise dimensional verification

- Optical Gaging Products (OGP) / Smart Scopes for

non-contact measurement - 3D Laser Scanning for fully visualizing even complex and hard-to-reach part surfaces during inspection

Complete, Data-Driven Validation and Inspection Services

Experiments (DOE)

(FAI)

& T1 Samples

Control (SPC)

Supporting Your Manufacturing Operation

With SyBridge, we can build your mold and also provide pre-production molding to support your manufacturing operation. We offer:

- Early production runs to establish qualified processes

- Short runs for premarket supply chain qualifications or low-volume needs

- Assembly capabilities as needed

FAQs

Tool and part validation establishes that your molds and parts meet strict quality standards through rigorous testing, inspection, and certified processes. Key aspects of SyBridge’s MFAT (Mold Final Acceptance Test) for the mold’s performance and the quality of the parts it produces include: dimensional verification of molded parts, part quality, mold function, process capability, cycle time confirmation, and documentation review—all verifying the mold is production-ready and meets your requirements.

We provide mold qualification, functional mold testing, scientific molding, IQ/OQ/PQ qualification, first article inspection, and turnkey validation.

SyBridge utilizes Coordinate Measuring Machines (CMM), Optical Gaging Products (OGP), and in-process verifications for precise dimensional checks.

Our validation process includes detailed documentation, capability studies, and DOE, ensuring full compliance and traceability for every project.