Engineered for Performance: Precision Injection Mold Tooling Design

Unlocking Efficiency and Innovation with Expert Tooling Design

In the competitive landscape of manufacturing, the foundation of successful injection molders lies in expertly engineered molds—tooling that defines efficiency, ensures quality, and drives innovation. Our dedicated team applies decades of experience and cutting-edge technologies to create precision injection mold tooling designs that consistently deliver exceptional results.

Designing & Engineering the Optimal Tooling for Your Success

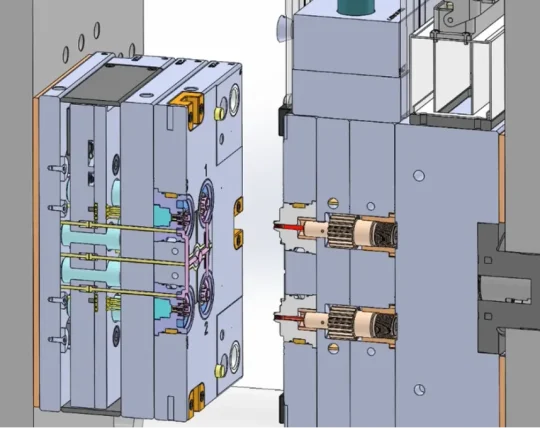

At SyBridge Technologies, we look beyond part design. We engineer injection mold tooling that’s production-ready, cost-efficient, and performance-optimized. Our engineering team works works alongside your team to understand total quality, cost, and delivery requirements in order to accelerate time to market and ensure manufacturability at scale.

Engineering Excellence in Action: Mastering the Details

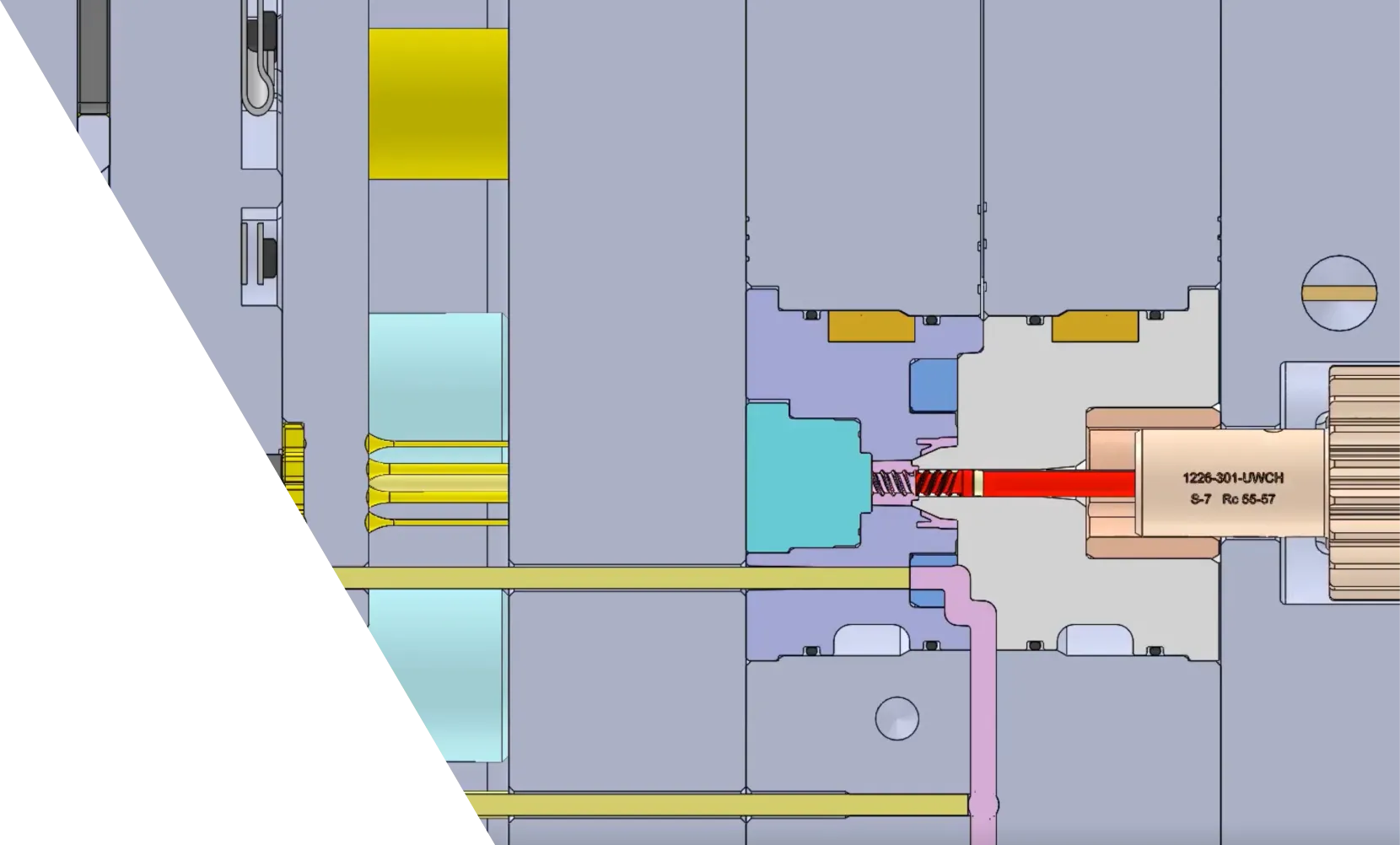

We embed manufacturability into the heart of our injection mold tooling design process, proactively identifying and resolving potential issues early on. Our Design for Manufacturability (DFM) and Design for Excellence (DFX) approach considers all critical factors, ensuring your tooling is optimized for performance, reliability, and cost-effectiveness.

Comprehensive Engineering Services for Every Mold

Development

Simulation

Analysis

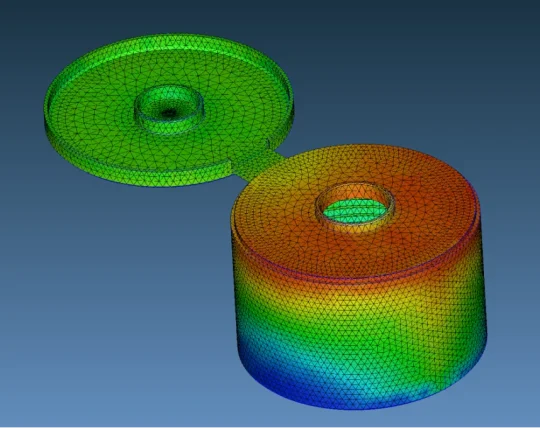

Simulation & Analysis for Critical Decision-Making

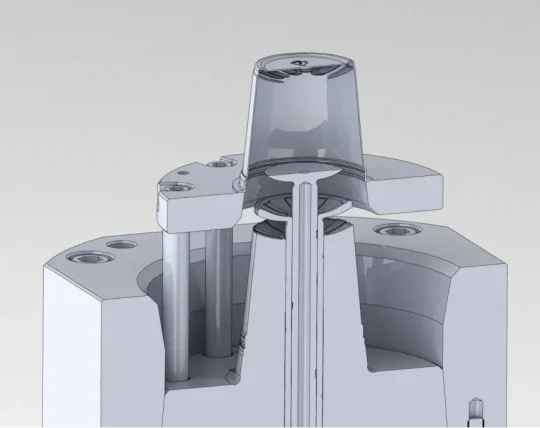

Ensure confidence at every stage by predicting performance before production. Our experienced team applies advanced simulation tools to validate and optimize every aspect of your precision mold before steel is cut. This includes detailed analysis of mold flow, cooling, cycle time, and design validation to ensure your mold is optimized for yield and repeatability.

Quality Parts Begin with Quality Molds

We engineer molds that deliver long-term performance, scalability, and cost control. We are relentless in our pursuit of optimized productivity, with meticulous attention to design elements like gating, venting, and the ongoing implementation of advanced technologies. The SyBridge Advantage provides engineered solutions including high-cavitation, multi-material, and family tools to optimize performance.

start the conversation

FAQs

Design for Manufacturability (DFM) is a core engineering process we use to proactively identify and resolve potential issues early in the injection mold tooling design. This ensures the tooling is optimized for long-term performance, reliability, and cost-effectiveness before steel is cut.

We use advanced simulation and analysis tools to predict performance before production. This includes detailed Moldflow & Cooling Simulation, Thermal Analysis, Structural / Stress Analysis, and Cycle Time Optimization to ensure high yield and repeatability.

Expert tooling design accelerates product development by engineering production-ready, cost-efficient, and performance-optimized tooling. This proactive approach, including DFM, avoids costly rework and delays often encountered during the manufacturing scale-up phase.

Conformal Cooling is an advanced design technique that optimizes the cooling channels within the mold. It is important because it significantly improves the efficiency of the cooling process, leading to a much faster and optimized cycle time for production.