Tooling Built

for the

Industrial World

Durable, repeatable solutions

engineered for high-

volume, high-performance applications

Industrial markets demand precision, repeatability, and the ability to scale under pressure. SyBridge delivers custom injection mold tooling for industries from material handling and construction to commercial equipment and power tools, helping manufacturers launch faster, improve reliability, and reduce total cost of ownership as a single-source partner for full lifecycle tooling.

Trusted Industrial

Tooling Expertise

We combine deep marketing knowledge and 50+ years of experience with a global network of engineers and facilities to keep your programs on track and your products in the field.

- 7 industrial-focused manufacturing facilities across the U.S., Canada, and Mexico

- ISO 9001:2015 certified at all industrial-focused manufacturing facilities in Canada and Mexico

- 300,000+ sq. ft. of dedicated industrial tooling space

- 50+ designers and engineers focused on industrial solutions

- End-to-end injection molding support: DFM, prototype and bridge tooling, production tooling, fixtures and gauges, tool and part validation, production components, and tool repair services

Molds for the Toughest Markets

We engineer and maintain high-performance tools for a wide range of industrial applications—delivering durability, repeatability, and compliance for the most demanding programs.

Material Handling & Storage

For manufacturers of products that transport, protect, and store goods across logistics and warehouse operations, SyBridge delivers robust molds that balance strength, efficiency, and cycle time. We’re experts in tooling for:

- Plastic pallets and skids

- Storage totes and bins

- Industrial containers and hoppers

- Bulk storage units

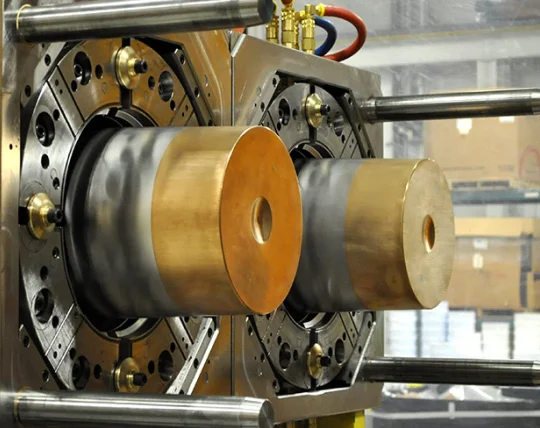

Pails & Buckets

As one of North America’s largest pail and bucket tooling companies, SyBridge consistently ranks #1 for tools with the fastest cycle times. Our robust, high-performance tools produce round and square pails for both industrial and food & beverage applications—engineered for durability, stackability, and maximum production efficiency.

- Small to large sizes

- Round and square configurations

- Snap-on or threaded lids

Building & Construction

SyBridge supports OEMs and contract manufacturers in the construction market with injection mold tooling that produces strong, durable, and precise plastic parts. Our tooling enables production of:

- Plumbing and water system components

- HVAC Housing

- Utility and electrical conduit fittings

- Roofing and exterior accessories

- Infrastructure-grade mounting brackets

Animal Care & Containment

From heavy-duty carriers to modular systems for commercial use, SyBridge provides injection mold tooling for a wide range of animal care products. Our solutions are used for the production of:

- Pet and livestock crates/carriers

- Modular kennel systems

- Plastic gates and fencing

- Feed and watering containers

- Litter boxes and trays

FAQs

We design and build injection mold tooling for a wide range of industrial applications, including material handling equipment, storage systems, construction components, power tools, and animal care products.

Yes. We provide full lifecycle services, including DFM, prototyping, bridge and production tooling, fixtures and gauges, tool and part validation, production components, and ongoing tool repair and maintenance.

Our tools are engineered to withstand high-volume production and produce parts with strength, dimensional stability, and repeatability. We focus on robust steel selection, cooling design, and optimized cycle times to deliver both performance and efficiency.

We operate 8 industrial-focused facilities across the U.S., Canada, and Mexico, with over 300,000 sq. ft. of dedicated tooling space and ISO 9001:2015 certifications across our Canadian and Mexican sites.

Yes. We have extensive experience with large-scale tooling for plastic pallets, containers, totes, bins, and other bulk storage and logistics products, ensuring structural integrity and consistent performance.